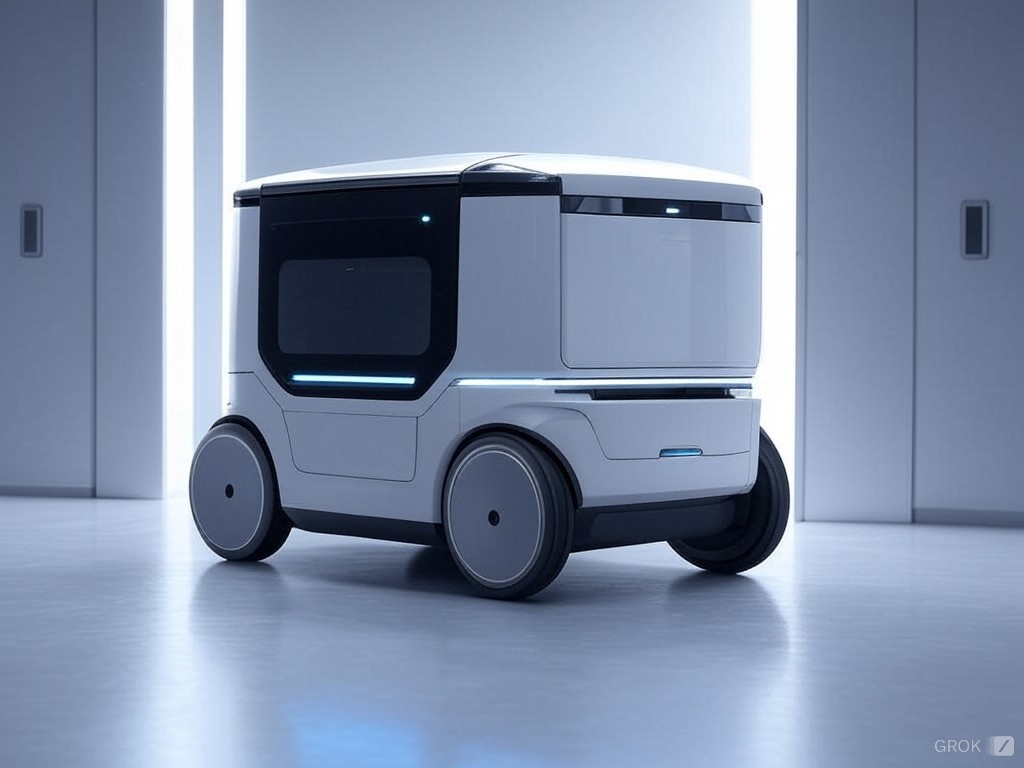

🚀 Modular 4-Wheel Robot with Swappable Bodies and Ejector Battery System

This design evolves your concept into a highly versatile, modular robotic platform inspired by swappable car bodies (e.g., transforming a VW Bug base into an SUV, delivery cart, or Mars rover). The core is a standardized "base" chassis housing all essential systems—drive, electronics, and battery—while the upper "body" detaches and swaps in minutes for task-specific configurations. The battery uses your ejector-razor mechanism: a drive-over station pushes a fresh tray in from the front, ejecting the old one out the back onto a charger. This keeps the system rugged, scalable, and downtime-free for applications like urban delivery, planetary exploration, or industrial automation.

🎯 Core Design Principles

- Modularity: Base is universal (all "guts"); bodies attach via quick-release couplers (e.g., ISO-standard pins or magnetic latches) for 2-5 minute swaps.

- Autonomy & Safety: Onboard AI handles navigation and docking; redundant sensors ensure safe swaps.

- Scalability: Base supports 10-50kg payloads; stations network for fleets.

- Ejector Simplicity: No complex robotics—linear push-through for batteries, like a cassette deck.

🔧 Base Chassis Design

The base is a low-slung, all-wheel-drive platform (60cm L × 40cm W × 20cm H, ~15kg) with everything vital integrated. It's the "VW Bug engine" equivalent—compact, powerful, and body-agnostic.

| Component | Description | Rationale |

|---|---|---|

| Frame | Powder-coated aluminum skeleton with mounting rails for bodies. IP67-sealed. | Durable for rough terrain; rails ensure precise body alignment (±2mm). |

| Wheels & Drive | Four hoverboard-sized (20cm dia.) brushless DC motors (200W each) with rubber treads and encoders. Top speed: 1.5m/s. | High-torque for loaded configs (e.g., Mars-like rocks); differential steering for tight maneuvers. |

| Battery Bay | Front-facing through-slot (25cm × 15cm) with low-friction rollers; pogo-pin connectors for power/data. | Enables ejector swap: new battery pushes old out rearward during drive-over. |

| Electronics | Central bay with NVIDIA Jetson Orin (compute), ROS2 OS, IMU/LiDAR suite, and Wi-Fi/5G. | Powers all bodies uniformly; low-battery auto-routes to station. |

| Suspension | Active hydraulic dampers per wheel. | Adapts to body weight changes; levels for stable docking. |

🔄 Swappable Body Modules

Bodies are plug-and-play "skins" that bolt onto the base, transforming function without rewiring (power/data via umbilical connectors). Swap via lift-jack or overhead hoist.

| Body Type | Description | Key Features | Use Case |

|---|---|---|---|

| Delivery Cart | Oversized ice chest-style enclosure (80cm L × 50cm W × 60cm H, insulated aluminum). | Lockable bins, GPS-tracked compartments, 20kg capacity. | Urban last-mile logistics; keeps perishables cool. |

| Mars Rover | Rugged, low-profile shell with extended rockers and solar panels. | Dust-proof seals, 360° cameras, sample scoop arm; 15kg payload. | Extraterrestrial scouting; simulates rough-terrain autonomy. |

| Robotic Arm | Open-frame with 6-DOF manipulator (e.g., UR5-inspired, 5kg reach). | Tool changers, force sensors; integrates with base LiDAR. | Warehouse picking, assembly, or inspection tasks. |

| SUV Equivalent | Enclosed cabin with seating/storage for tools. | Weatherproof doors, roof rack; up to 30kg load. | Field maintenance or multi-operator transport. |

⚡ Electronics and Control System

- Unified Controller: Jetson handles base ops; bodies add task-specific plugins (e.g., arm kinematics for robotic config).

- Sensors: Base: LiDAR/IMU/ultrasonics for docking. Bodies: Add-ons like thermal cams (delivery) or spectrometers (rover).

- Software: Modular ROS2 nodes—base for mobility/battery, body-specific for payloads. App for fleet management and swap scheduling.

- Power: 48V system (5kWh base battery); bodies draw via connectors, with solar trickle on rover body.

🔌 Drive-Over Battery Swap Station

A minimalist pad (1m × 1m, embedded in floors/paths) for seamless recharging. Robot rolls forward at walking speed; swap completes in 10s.

| Component | Description | Rationale |

|---|---|---|

| Ramp/Guides | 5° entry ramp with wheel grooves and alignment bumps. | Ensures straight approach; no full stop needed. |

| Pusher Mechanism | Pneumatic ram (10N force) feeds pre-loaded battery tray into front slot. | Razor-like eject: displaces old tray rearward onto chute. |

| Ejection Dock | Angled shelf with spring-loaded charging pins; queues 6 trays. | Auto-connects ejected battery; charges to 80% in 45min. |

| Verification | Load cells/IR sensors check insertion; NFC for tray ID. | Confirms swap; green LED signals "go." |

| Enclosure | Flush-mount concrete with optional solar hood. | Low-profile for paths; weatherproof, easy to install. |

- Low battery → Navigate to station.

- Roll up ramp → Pusher activates on alignment.

- New tray slides in → Old ejects to dock.

- Verify power → Drive off.

⏱️ Swap Timing Breakdown

| Step | Duration |

|---|---|

| Approach & Align | 4s |

| Push/Eject | 3s |

| Total | 10s |

🛡️ Safety and Implementation

- Safeties: E-stop on base; body-specific overrides (e.g., arm collision detection). UPS for 2min emergency drive.

- Reliability: MTBF >10k hours; predictive logs for maintenance.

- Prototyping: Start with 3D-printed base mockup, off-shelf motors. Cost: Base $800, bodies $300-1000 each, station $1500.

- Extensions: API for custom bodies; integrate with drone docking for hybrid fleets.

🎉 Final Vision

This final draft captures the full vision: a chameleon-like base that "transforms" via bodies, powered by effortless battery ejects. It's practical for Earth or beyond—ready for your tweaks or build phase!

If you need CAD sketches, BOMs, or code starters, hit me up.